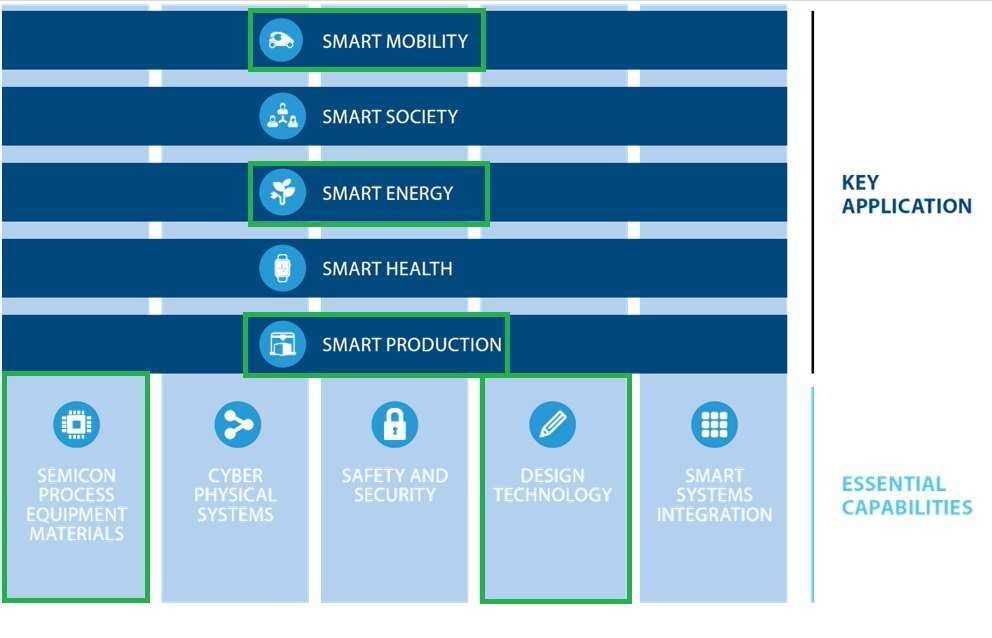

The first “Key Application” for REACTION is the key objective of sustainable “Smart Energy”, in particular the focus is mainly the market of PV inverters and bi-directional power conversion systems for renewable energy and micro grid applications. Inside the REACTION project, ITALEAF has the objective to demonstrate the SIC benefit in the photovoltaic (PV) and battery energy storage system (BESS) inverters developed addressing the microgrid application. ITALEAF is a big holding operating in the cleantech and in innovative industrial productions sectors, it is the main shareholder of in its company portfolio there is Terni- Energia, a global company in the field of renewable energy, waste management and energy efficiency that is the first Italian smart energy company.

Any small-scale localized station with its own power resources, generation and loads and definable boundaries qualifies as a microgrid. A microgrid is an electrical system that includes multiple loads and distributed energy resources that can be operated in parallel with the broader utility grid or a small, independent power system.

A smart grid is a modernized electrical grid that uses information and communications technology to gather and act on information, such as information about the behaviours of suppliers and consumers, in an automated fashion to improve the efficiency, reliability, economics, and sustainability of the production and distribution of electricity. The microgrids are the an evolution of the electrical smart grid permitting to increase reliability with distributed generation, efficiency with reduced transmission length, and easier integration of alternative energy sources.

In modern micro-grids either grid-tied or independent inverters are the essential piece of equipment that changes the direct power (DC) from the PV array to alternating power (AC) used in the electrical grid. Bidirectional inverters (often called Power Conversion Systems – PCS) are the interface between the local distribution and the battery storage system, which are becoming more and more important to reach micro grid stability and efficiency objectives. Not only does the inverter and PCS convert DC to AC power and vice versa, but it also regulates the grid frequency and voltage and the PV system performance.

Will be developed two inverters for wind and PV-wind applications. Small energy systems can be roof-based or ground-based, and they are sold to residential, commercial, industrial, agricultural and transportation utilities. The aim is to shown the SiC advantages for domestic and industrial applications. Therefore, the challenges will be to develop inverters for these applications at the lower cost, which will require employing very high switching frequencies. SiC technology allows increase switching frequency, and high frequencies lead to reduce size of passive components and its cost. However, the higher the frequency, the greater the EMI (electromagnetic interference) problems are. Therefore parasitic inductance and “skin effect” phenomena arise and become crucial considerations for bus bar designs because produce additional losses and over voltages. To reduce stray inductance and the switching loop, planar busbar designs can be used. Finally, a hybrid PV- wind experimental installation will be used for testing inverters for domestic (1ph) and industrial (3ph) applications. The key of these applications is the total cost should guarantee profitability with respect to the current Si technology, with an enhancement of compactness and efficiency. Furthermore, it will focus on the evaluation of SiC devices in Medium- Voltage PV applications, analysing the performance and the viability of the SIC devices in high power applications. This power converter will also include an intermediate DC-DC converter in order to include an electrical storage element to the renewable energy generation system.

The second “Key Application” for REACTION is the real key objective of a sustainable ‘Smart Mobility’ and, in this respect, project SiC devices will easily penetrate the automotive market as now described.

There are several applications in vehicles where SiC have an competitive advantage enabling more compact systems with higher efficiency and simpler cooling systems. The motor drives, DC-DC converters and battery charging systems a few examples where SiC devices could have a positive impact. The initiative to start the first worldwide 8” SiC Pilot Line would lower the cost and threshold to switch from silicon technology considerably.

SiC power devices would improve the system performance greatly. The high power, speed and temperature features of SiC devices enables efficient, compact drives and DC/DC converters with less cooling requirement. Thus, energy consumption is reduced directly by the higher efficiency by also indirectly by the more compact design with less weight. Electrification of vehicles have been an on-going activity for several years with reduced energy consumption due to more efficiency drive but also regeneration of breaking energy. Also in heavy vehicles such as harvesters and log handlers electric drives can improve performance and reducing fuel consumption by up to 50% due to extreme drive cycles where mechanical drives rarely operate under optimal conditions.

Of course a main key objective is a sustainable ‘Smart Production’ too to support the migration from legacy to next generation of compound

production. It is strongly felt that European industrial production is facing and, more than ever, will face soon stronger and stronger global competition in new materials. The development of the European leadership in automation and process control is therefore key to increase European competitiveness in production in general, but only if Smart Production technologies that stay behind will remain or became competitive; this ambitious aim will be surely enabled by this proposal, allowing the first European 8” SiC Pilot Line. This world leading disruptive 8” SiC technology production enable a cornerstone for the reindustrialisation of the entire Europe.

All REACTION manufacturing partners represent the engine that drives the economic growth and development of their countries of origin thanks to their ability to produce wealth and employment, make associated industries and services flourish, and contribute to the financial, economic and social stability of their countries. As regards Italy (coordinator country) it has been stated, by law, a clear interest to create an environment that is favourable to business and there is now an Industrial 4.0 policy on top of the Italian Government’s agenda and, in this context, there is with REACTION a special commitment by MiSE to focus and funds this proposal (as after detailed) in the Industry 4.0 context.

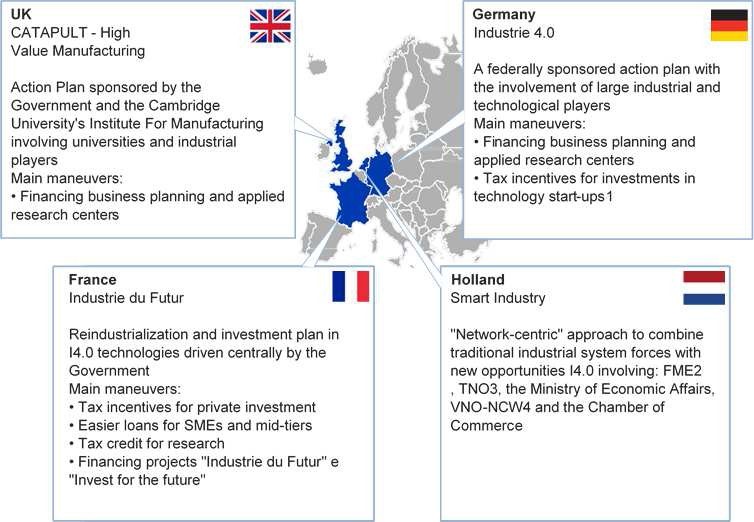

In this clear direction are also Germany, France, UK (REACTION countries) and Holland; here below, are summarized their 4.0 industry programs already launched.

In this respect all the equipment that will be developed by REACTION will be consistent with the National Industry Plans 4.0, as are functional for the technological and digital transformation of businesses according to the “Industry 4.0” Italian model (appendix A of Law No 11 of 23 December 2016) being:

• Controlled by means of CNC (Computer Numerical Control) and / or PLC (Programmable Logic Controller),

• Interconnected with factory-installed IT systems with remote upload of instructions and / or part program,

• Automated integrated with the factory logistics system and / or with the other production cycle machines,

• Interfaced between man and machine in a simple and intuitive way,

• Compliant with the latest safety, health and work hygiene parameters,

• Remote maintained and / or under telediagnosis and / or remote controlled,

• Continuously monitored about working conditions and process parameters through appropriate set of sensors and adaptivity to process leads,

• Intelligent devices, instrumentation and components will be embedded for the integration, sensing and / or interconnection and automatic control of processes used in the modernization or revamping of existing production systems,

• Equipped by signalling systems for the occurrence of anomalies or process alien or dangerous substances, integrated with the factory system and able to alert operators and / or stop machines and plants,

• Installed with monitoring systems to assure and track the quality of the product or production process and enable them to qualify production processes in a documentable way and connected to the factory information system.

As regards the relevant facilities they will be compliant with Industry 4.0 because they will enable:

• Process monitoring systems to assure and trace the quality of the product or the production process and enable it to qualify production processes in a documentable way and connected to the factory information system,

• Filters and systems for the treatment and recovery of water, air, oil, chemicals, powders with filtering efficiency reporting systems and the presence of process or malfunctioning abnormalities or substances, integrated with the factory system and capable of alert operators and / or stop machine and plant activities,

• Intelligent components, systems and solutions for efficient management, efficient use and monitoring of energy and water consumption and emissions reduction,

• Intelligent human-machine interfaces (HMIs) that assist the operator in the safety and efficiency of machining, maintenance, and logistics operations.

Definitely REACTION proposal strategy will doubtless address and support a top level smart production that will doubtless overcome any stakeholder hesitations on SiC material production in Europe.